Case Study: 6mm Hex Tool

The client approached LTS with an urgent need to create CAD models and prints for a custom fastener removal tool that they needed to use in an upcoming maintenance job in a power plant. The drive attachment design is based on a cam gripping technology that the client has used in other sizes, but never in one so small. The basis of the design is to provide a secure grip on a female hex profile, without risking stripping the head, so that stubborn bolts can be reliably removed.

We started the project by interrogating their existing tool designs, and miniaturized the parts and adapted features to be contained within the small envelope. A high-level concept design was submitted for client approval before CAD models were made.

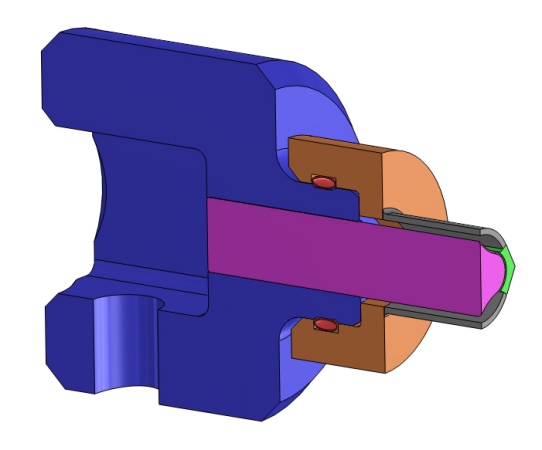

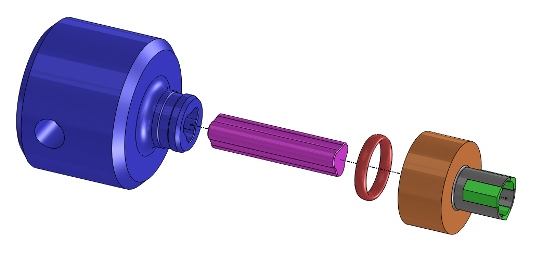

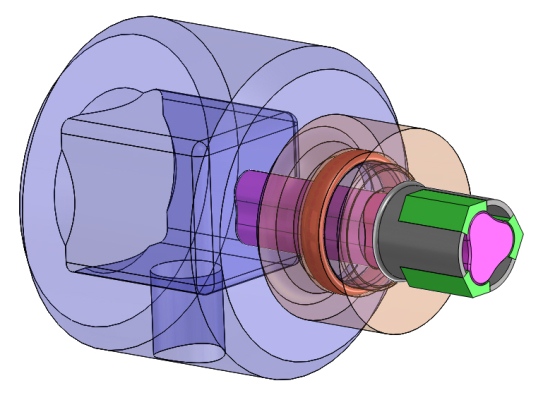

CAD model were then made of all of the parts, sub-assemblies, and final assembly. The cam profile was particularly important to size precisely so that it would work properly on a range of hex sizes seen in the field, even when worn in due to their age. The front most cam ‘shoes’ would be held together with an over-molded rubber membrane.

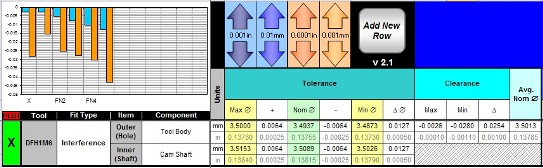

Then, an engineering fit study was performed on the critical components that mate with each other, including the central purple camshaft that would press into the blue tool body.

Engineering drawings were made for each part, and assembly. Materials and manufacturing processes, and surface finish were thoroughly specified, as well as comprehensive tolerancing using GD&T and limit dimensions.

![]() 6mm Hex Tool Assembly Drawing.pdf

6mm Hex Tool Assembly Drawing.pdf

Lastly, quotes were obtained from a few qualified machine shops and suppliers. The design was completed quickly, and LTS was able to meet the clients urgent deadline for their high-profile plant maintenance job.