Case Study: Volkswagen R32 Paddle Shifter

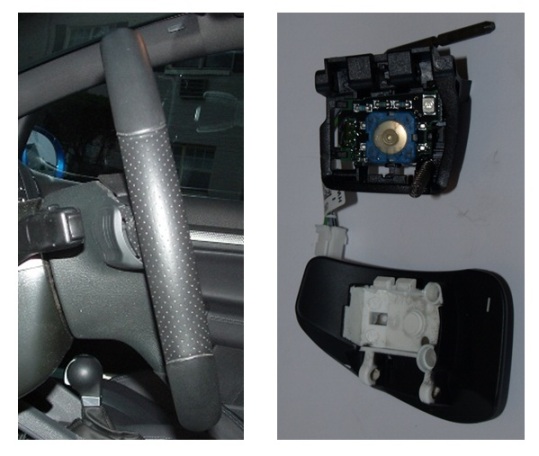

The client wanted to offer an after-market replacement shift paddle for the VW R32, the high performance version of the Golf. The goal was to achieve a sleek design that extends the paddle flaps so that they can be more easily actuated. There are some other products that use double sided tape to apply paddle extensions, but the client wanted a fully bolt-on replacement that is compatible with the OEM interface. The 1st step was reverse engineering of OEM paddle shifter. This is what it looks like installed in a car, and then removed:

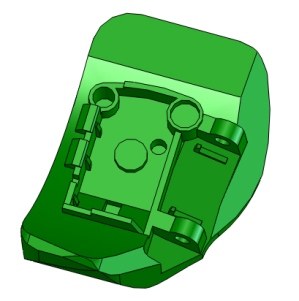

Then a 3D model of OEM paddle was created for reference geometry. Note all of the intricate features that interface with the electronic sensor:

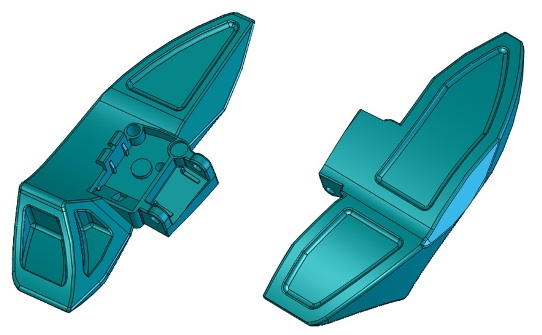

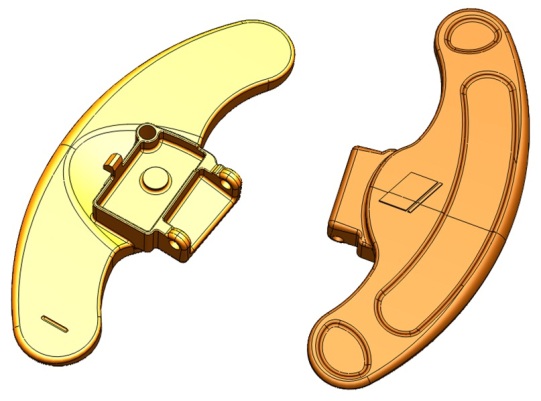

Next a 3D model of a new paddle design was made, based on customer specifications:

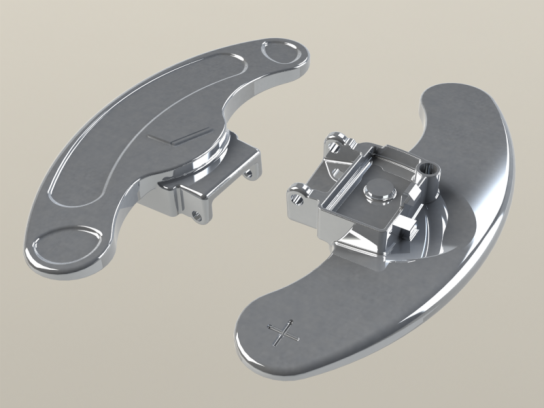

The design was iterated a few times, and in the end, we went in a different direction, with a more contoured design:

Photo renderings were made for the website and marketing purposes.

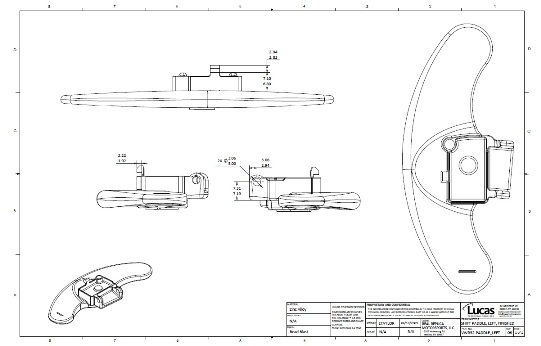

Manufacturing drawings were created, and sent to the manufacturer.

The final parts were made by a low-volume process called Spin Casting. The shift paddles are now being sold by a premium after-market parts supplier.